fittings and hose lines

for centralised lubrication systems

The high pressure hose

General

In the vehicle and industry sectors, high pressure hoses are employed in central lubrication systems that are used in the automated maintenance of the factory equipment, vehicles and machinery. For the utilisation of high-pressure hoses in a central lubrication system, the high-pressure hose which is applied as the main pipe of the central lubrication system from the piston pump to the main distributor, but also from the main distributor to secondary distributors located downstream, has to withstand several hundred bar pressure.

Other requirements of the high-pressure hose

Besides being resistant to pressure, the high-pressure hose has to have a low weight. The high-pressure hose should be characterised by a high bending strength and flexibility. The exterior covering of high-pressure hoses has to be resistant to abrasion, weathering, UV light and ageing.

Depending on its field of application, it should also be temperature resistant and show resistance to chemicals, detergents and solvents.

Construction and material of high-pressure hoses

The construction of high-pressure hoses is not always the same, the qualities are different. The inner layer, the “core” of the  high-pressure hose, has to consist of a material that is as smooth as possible as well as non-porous, because the pressure loss of the medium that needs to be transported, for example the lubricant for the maintenance of your system, should be kept low on its way through the hose. In which way a high-pressure hose is finally constructed obviously depends on the field in which it will be applied.

high-pressure hose, has to consist of a material that is as smooth as possible as well as non-porous, because the pressure loss of the medium that needs to be transported, for example the lubricant for the maintenance of your system, should be kept low on its way through the hose. In which way a high-pressure hose is finally constructed obviously depends on the field in which it will be applied.

The 840 bar high-pressure hoses of Fritsche GmbH & Co. KG, which are employed in central lubrication systems, consist of a polyamide 6 (PA6) tube in their interior, which is coated by and agglutinated with a polyester cover, while the material that is attached to the outer layer is made of polyurethane.

The peculiarity here is the bonding with which the plating is also connected to the polyester cover and the inner tube. Moreover, the offered high-pressure hoses are characterised by a very low inner and outer diameter and a small bending radius. But the high-pressure hose described here is still solid and meets high needs for security because it is designed not only to withstand high pressure but also to endure the constant movements that accompany the works of the central lubrication system and the transport of the lubricant.

Furthermore, the high-pressure hose is also suitable for the operation of manual lubrication systems.

Installation of the high-pressure hose

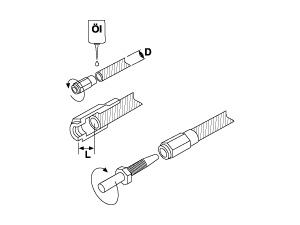

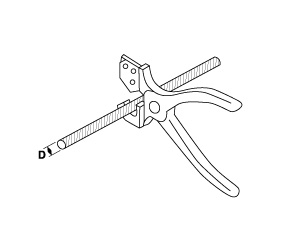

The high pressure-hose is delivered in the form of rolled material and can be cut to length according to your needs.

A threaded sleeve is threaded to the resulting hose endings, in which a pipe socket is again screwed in. As a result, the top of the pipe socket sinks into the inner tube of the high-pressure hose. By this action, the high-pressure hose is grouted in the threaded sleeve automatically and pressure-tightly.

It has to be merely made sure that the threaded sleeve and the pipe socket are lightly greased or oiled during assembly in order to prevent damaging of the plating or the inner core of the high-pressure hose.

Both the threaded sleeve and the pipe socket are offered in different versions by Fritsche GmbH & Co. KG. The products are available in steel with various surface coatings or in stainless steel out of the high-quality material 1.4571/316ti. Regardless of which version you choose and which design is the best choice for your purpose – for all of the threaded sleeves and pipe sockets we provide, you only need two spanners or ring spanners, so only standard tools that can be found in every workshop are required. That is important – you do not need any special tools such as a compactor. The high-pressure hose has only to be cut in the suitable length, which is necessary to connect the desired items – for example to connect the distributor to the depository. For assembling, your calculation of the length of the high-pressure hose must consider the threaded sleeve and the selected pipe socket for each hose end.

|

|

Conclusion

We have the appropriate offer for any requirement and use.

From our broad product range, you can choose the right material for your individual requirements of a lubricant feed for your maintenance work.

Your Fritsche team will be pleased to advise you in detail.

More Information:

Centralised Lubrication •